Bergetar pengumpan Boratas Stationary Vibro Feeder VB Series baru

PDF

Bagikan

Facebook

WhatsApp

Viber

Telegram

Tertarik dengan iklan?

1/10

PDF

Bagikan

Facebook

WhatsApp

Viber

Telegram

Harga:

berdasarkan pemintaan

Buat penawaran harga

Hubungi penjual

Merek:

Boratas

Model:

Stationary Vibro Feeder VB Series

Tipe:

bergetar pengumpan

Tahun pembuatan:

2024

Bobot bersih:

1.200 kg

Lokasi:

Turki Kemalpaşa / İzmir8800 km dari Anda

Turki Kemalpaşa / İzmir8800 km dari Anda

Dipasang pada:

26 Des 2024

Machineryline ID:

ME37438

Mesin

Daya:

8.71 HP (6.4 kW)

Bahan bakar:

elektrik

Kondisi

Kondisi:

baru

Dokumen

Layanan pengiriman kendaraan

Penting

Penawaran ini hanya sebagai pedoman. Silakan tanyakan informasi secara persis dari penjual.

Tips pembelian

Kontak penjual

BORATAS STATIONARY/MOBILE CRUSHING AND SCREENING EQUIPMENT

Dalam stok:

100 iklan

1 tahun di Machineryline

4.7

3 ulasan

Subscribe ke penjual

Askar Muratbek Uulu

Bahasa:

Rusia, Turki, Inggris

Alamat

Turki, Aegean Region, Kemalpaşa / İzmir, Bağyurdu Organize Sanayi Bölgesi Anadolu Cad. No:8

Waktu lokal penjual:

21:37 (+03)

Kirim pesan

Kontak penjual

BORATAS STATIONARY/MOBILE CRUSHING AND SCREENING EQUIPMENT

Turki

Turki

1 tahun di Machineryline

4.7

3 ulasan

Subscribe ke penjual

+90 507 514...

Tampilkan

+90 507 514 42 28

Tanya penjual

PDF

Bagikan

Facebook

WhatsApp

Viber

Telegram

Menjual mesin atau kendaraan?

Anda dapat melakukannya dengan kami!

Iklan yang serupa

harga berdasarkan permintaan

2024

Daya

29.93 HP (22 kW)

Bahan bakar

elektrik

Hubungi penjual

harga berdasarkan permintaan

2024

Daya

61.22 HP (45 kW)

Bahan bakar

elektrik

Hubungi penjual

harga berdasarkan permintaan

2024

Daya

50.34 HP (37 kW)

Bahan bakar

elektrik

Hubungi penjual

harga berdasarkan permintaan

2025

Hubungi penjual

€10.000

≈ US$10.300

≈ Rp 167.000.000

2023

Daya

1000 HP (735 kW)

Bahan bakar

elektrik

Hubungi penjual

€10.000

≈ US$10.300

≈ Rp 167.000.000

2023

Daya

61223 HP (45000 kW)

Bahan bakar

elektrik

Hubungi penjual

€10.000

≈ US$10.300

≈ Rp 167.000.000

2023

Daya

28.71 HP (21.1 kW)

Bahan bakar

elektrik

Hubungi penjual

harga berdasarkan permintaan

2024

5 m/h

Bahan bakar

diesel

Hubungi penjual

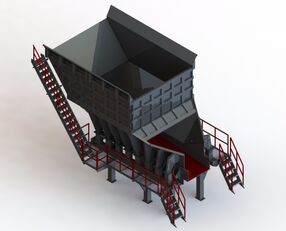

Key Design Features:

1. Tailored Sizing for Optimal Material Handling:

The Vibro Feeders of the VB Series are crafted in different sizes, offering a bespoke solution for material structure and capacity. This versatile design ensures efficient material handling, regardless of material hardness and abrasiveness.

2. Durable Construction:

The feeder boasts a resilient body and abrasion-resistant plates, contributing to its durability and longevity under challenging operational conditions.

3. Cost-Effective Operation:

Designed with low operating costs in mind, the Vibro Feeder VB Series combines efficiency with economic considerations, enhancing overall system sustainability.

Significance of Hoppers:

- Strategic Material Loading: Positioned at the forefront of the crushing plant, the hoppers play a pivotal role in systematic material loading, setting the stage for efficient material processing.

Material Handling Process:

- Efficient Material Transfer: Following the hoppers, the vibrating feeder efficiently transfers loaded materials either to the primary crusher or to a grizzly screen, ensuring a seamless and optimized material flow within the system.

- Enhanced Crusher Efficiency: The grizzly screen, adept at separating fine materials, contributes to heightened crusher efficiency. Separated materials proceed directly to the secondary crusher for further processing.

Structural Characteristics:

- Sturdiness and Shockproof Design: Engineered for robustness, these feeding machines withstand shocks and vibrations associated with material handling, ensuring reliable, long-lasting performance.

- Ease of Maintenance: Featuring simplified maintenance procedures, these machines minimize operating costs, ensuring a consistently high production rate.

Boratas Vibro Feeder VB Series stands as a testament to thoughtful design, precision engineering, and advanced material handling capabilities. It serves as an integral component in material processing systems, promoting efficiency, durability, and ease of maintenance.

For More Information Feel Free to Contact US!